What is the better choice for PVC material marking

Generally speaking, near or far infrared lasers (such as CO2 lasers) are used when marking on PVC materials. The most common far infrared machine is carbon dioxide laser marking machine. The wavelength of this laser is 10.6u. This kind of marking machine can print yellow-red writing on PVC materials but the yellow-red marking of carbon dioxide laser on PVC materials is often not so popular.

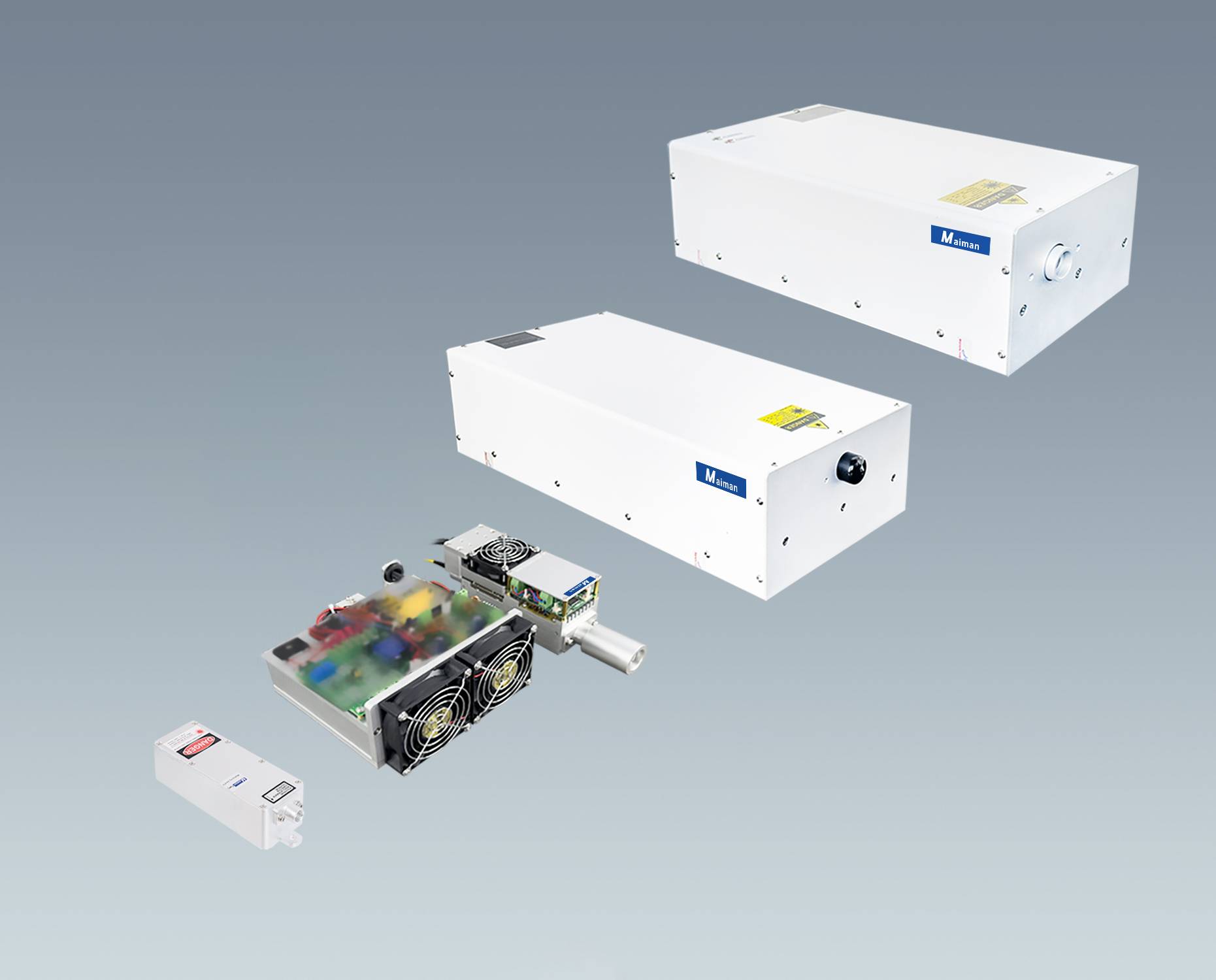

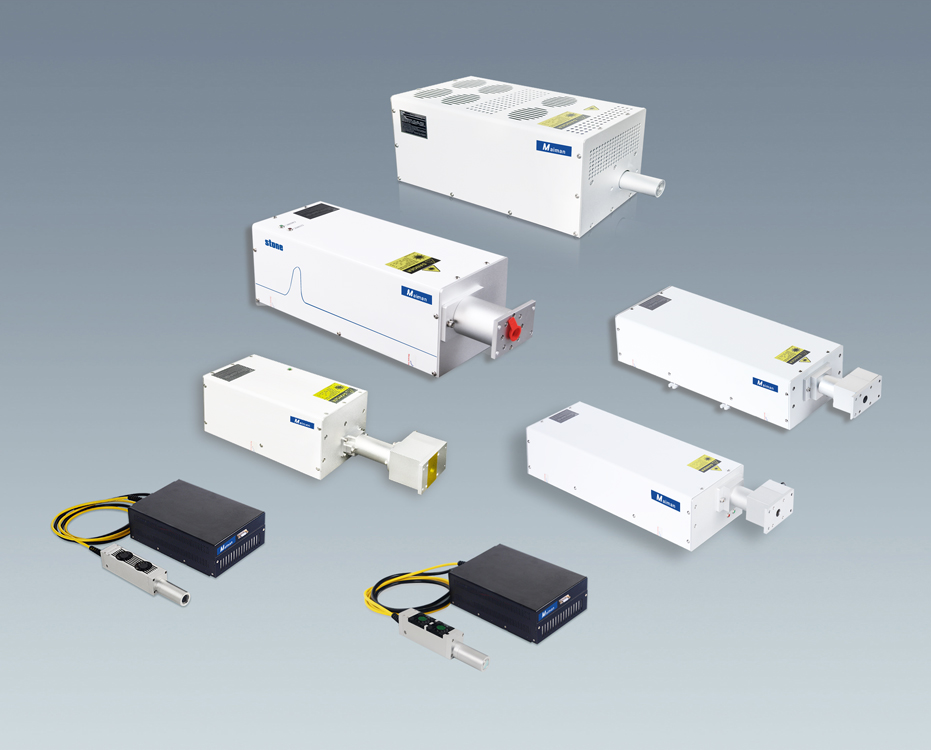

Advantages of fiber laser marking machine (1):

The wavelength of fiber laser is 1060nm which can be clearly engraved on PVC material and shows black. Fiber laser is considered to be the best laser to replace semiconductor laser and its application prospect on PVC material is also the most anticipated because the frequency of fiber laser marking machine can reach 80K, it is very small and the galvanometer with small spot can reach very high speed and the speed of marking line can reach or exceed the effect of CO2 laser.

Advantages of fiber laser marking machine (2):

The fiber laser marking machine adopts an integrated overall structure with no optical pollution and low power coupling loss and has many unique advantages in laser marking applications. It also has the advantages of low cost, maintenance-free operation, long service life of the laser and fast processing speed. The fiber laser marking machine has excellent beam quality and is small in size, suitable for harsh environments and is widely used in the marking of PVC materials.