Don’t worry about marking a QR code on a PCB board again

Marking QR codes or graphics on PCB circuit boards is a common method for PCB factories to trace production processes and quality control and automation brings good news to PCB marking. Laser marking machines that have been applied with automation technology have been able to complete fully automatic QR code marking during production process.

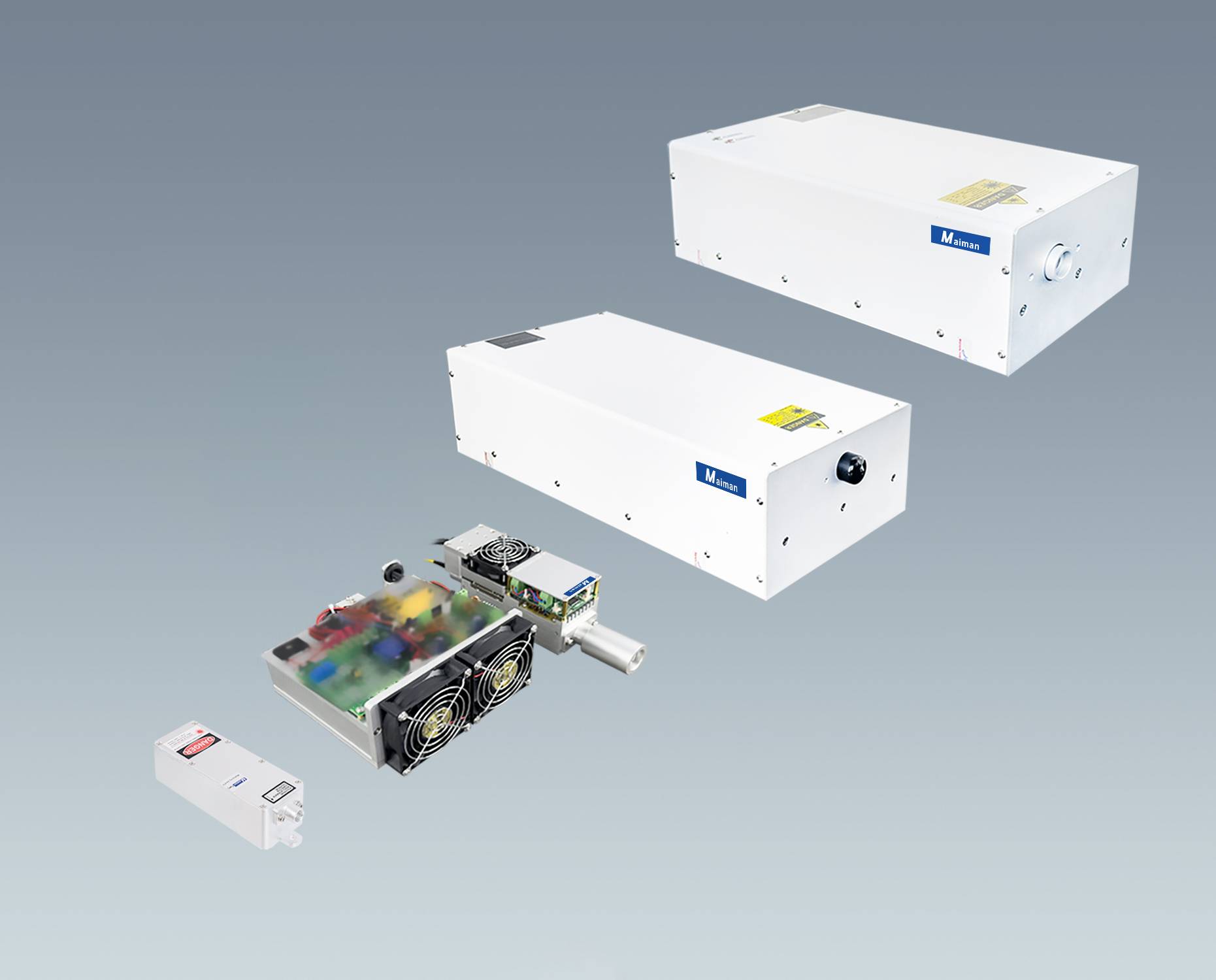

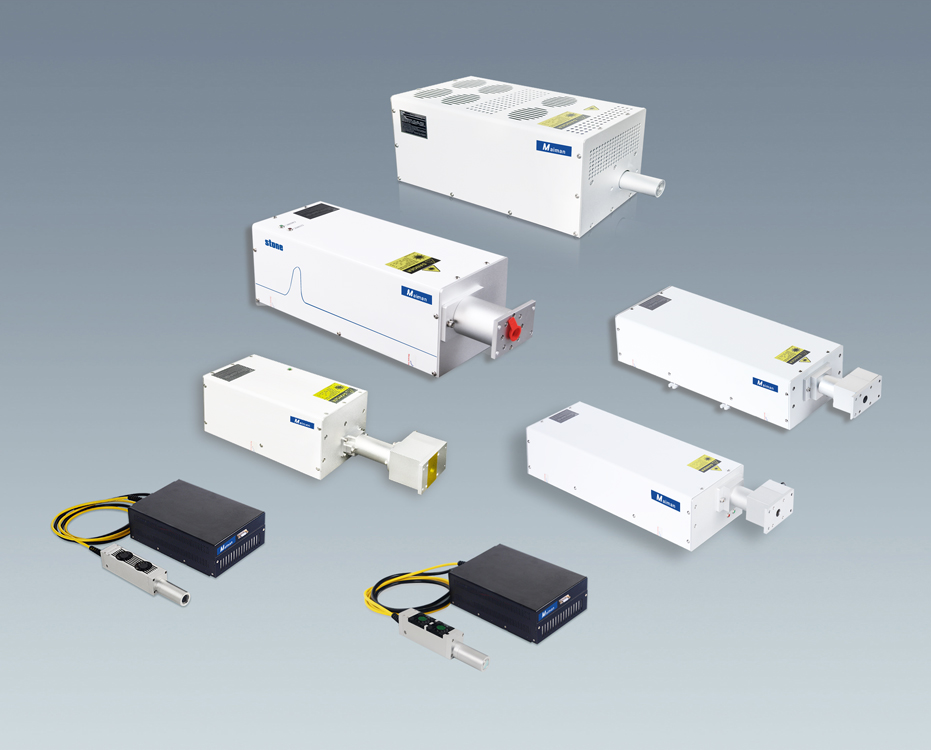

Laser coding machine is also called a laser marking machine. However the biggest difference between circuit board QR code laser marking machine and traditional laser coding machine is that this machine can realize automatic handling (customizable), automatic positioning and marking QR code. Equipped with Ultraviolet/optical fiber light source; it achieves high-precision marking of QR codes on PCB/FPC circuit boards and at the minimum can achieve 1.0×1.0mm QR code engraving with automatic reading and applying which represents an advanced level.

Laser marking technology has no contact processing, no consumables, no pollution and high precision. If you need to print double-sided PCB, it can also be equipped with automatic flip board which can solve the problem of coding on the surface of PCB circuit board in a one-stop way. Usually, the work that requires several people to cooperate can be fully automated by professional technology. Moreover, the circuit board QR code laser marking machine adopts the moving the working platform instead of the laser head mode which is more precise and stable than the traditional laser head moving mode. It can be equipped with or customized with conveying lines to achieve efficient production line.

The circuit board QR code laser marking machine can automatically generate a QR code for information such as raw material procurement, production process and technique, product batch, manufacturer, production date, product destination etc. and automatically engrave it on the surface of the circuit board through laser to realize better management of products!