Don’t let your laser cutting machine get heatstroke!

Everyone knows that the principle of the metal laser cutting machine is to use the high energy of the laser beam to focus on the metal surface, vaporize it and then achieve cutting through the relative movement of the laser head. So, when using the laser cutting machine in the hot summer, what do we need to do to avoid the heatstroke of the laser cutting machine?

When the laser cutting machine is cutting materials its temperature becomes very high, flammable materials such as chemical fiber clothes, documents etc. should not be placed next to the blanking steel plate or torch to prevent fire. Guide rails and racks tend to generate heat due to friction during use. Once excessive heat is generated, it will affect the material of the components. In order to prevent excessive heat generation, it is necessary to add lubricating oil before use.

The cutting site cannot store things that are prone to explosion when exposed to high temperature such as gas cylinders and air pipes which are best not to be left at the cutting site. When using a laser cutting machine, the air pipe and power cord should be suspended in mid-air and should not be placed on the guide rail or cutting area to prevent damage and accidents.

When using the cutting machine, you must concentrate and not be half-hearted. Many production accidents are caused by lack of concentration during operation. After use, turn off the power supply and air source and wipe the panel clean to ensure for next use.

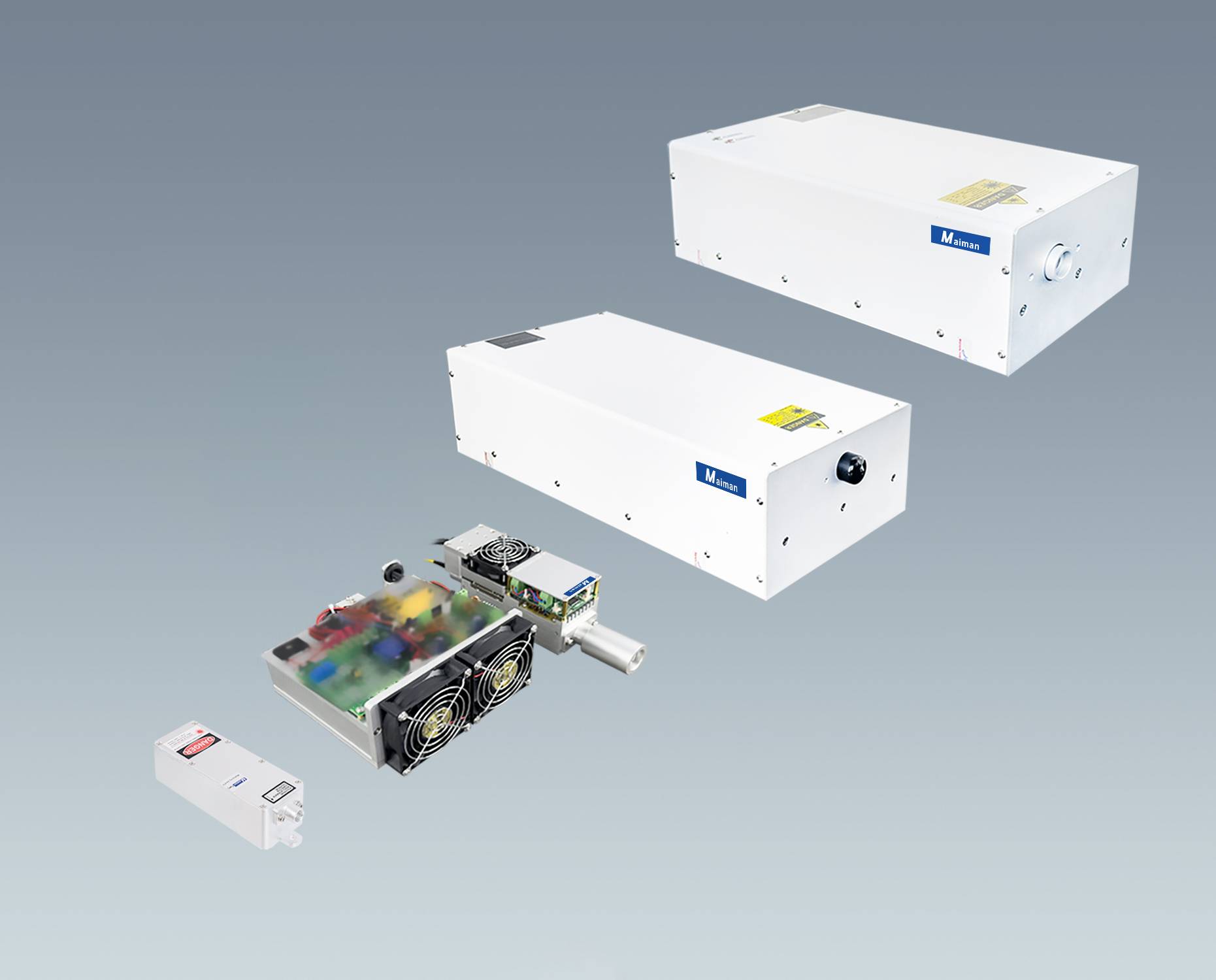

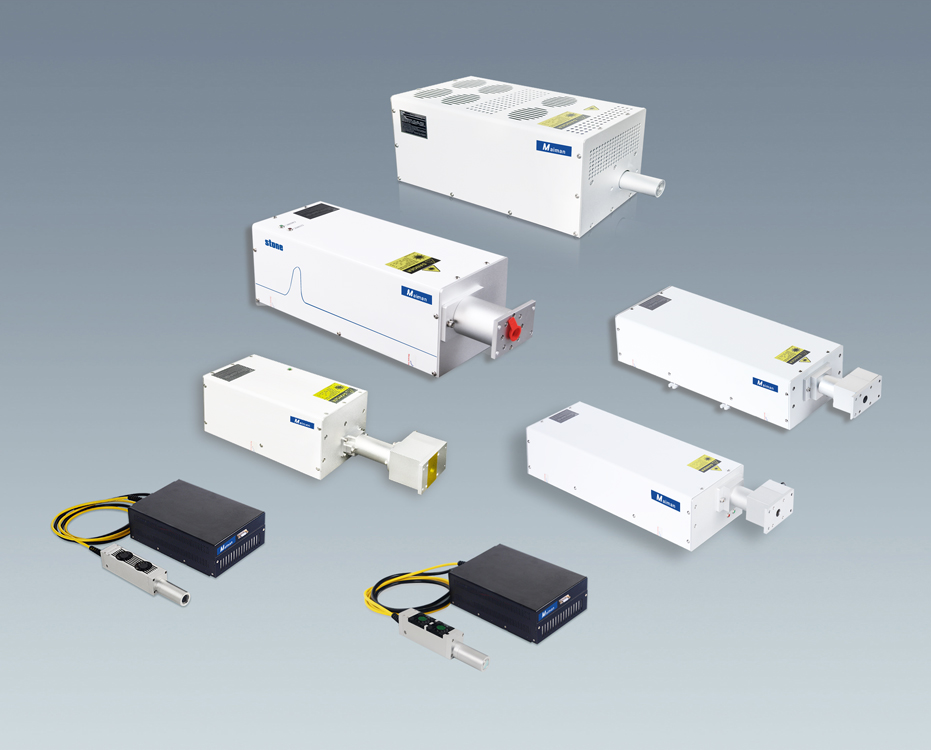

The summer is hot and “Three Musketeers” of laser equipment; the laser cutting machine, the laser marking machine and the laser welding machine all need to pay attention to the high temperature problem!