| Model No. -Stone Series | MMEPU-355-3 | MMEPU-355-5 | MMEPU-355-8 | MMEPU-355-10 | MMEPU-355-12 | MMEPU-355-15 |

| Model No.-Stone Plus Series | MMEPU-355Plus-3 | MMEPU-355Plus-5 | MMEPU-355Plus-8 | MMEPU-355Plus-10 | MMEPU-355Plus-12 | MMEPU-355Plus-15 |

| Optical Characteristics | ||||||

| Wavelength (nm) | 355nm±1nm | |||||

| Average Power (W) | >3W@30kHz | >5W@30kHz | >8W@40kHz | >10W@40kHz | >12W@40kHz | >15W@40kHz |

| Single Pulse Energy (uJ) | ~100uJ@30kHz | ~160uJ@30kHz | ~200uJ@40kHz | ~250uJ@40kHz | ~300uJ@40kHz | ~375uJ@40kHz |

| Pulse Width (ns) | ~15ns@30kHz | ~15ns@40kHz | ||||

| Frequency Range | 20-500kHz | 40kHz-500kHz | ||||

| Pulse Stability | <3% rms | |||||

| Long Term Stability | <±3% | |||||

| Beam Characteristics | ||||||

| Polarization Ratio | Horizontal;>100:1 | |||||

| Beam Diameter | ~0.8mm(at exit)/~5mm(6X beam divergence) | |||||

| Beam Circularity | >90% | |||||

| Spatial Mode | TEM00, M²< 1.3 | |||||

| Operating Specifications | ||||||

| Warm-up Time | <15 minutes from cold start | |||||

| Electrical Requirement | DC12V,350W | DC15V,350W | DC18V,350W | |||

| Ambient Temperature | 10-35℃, RH<80% | |||||

| Storage Conditions | -10-40℃, RH<90% | |||||

| Physical Characteristics | ||||||

| Cooling System | Water-Cooled | |||||

| Water Temperature (laser inlet) | 25℃ | |||||

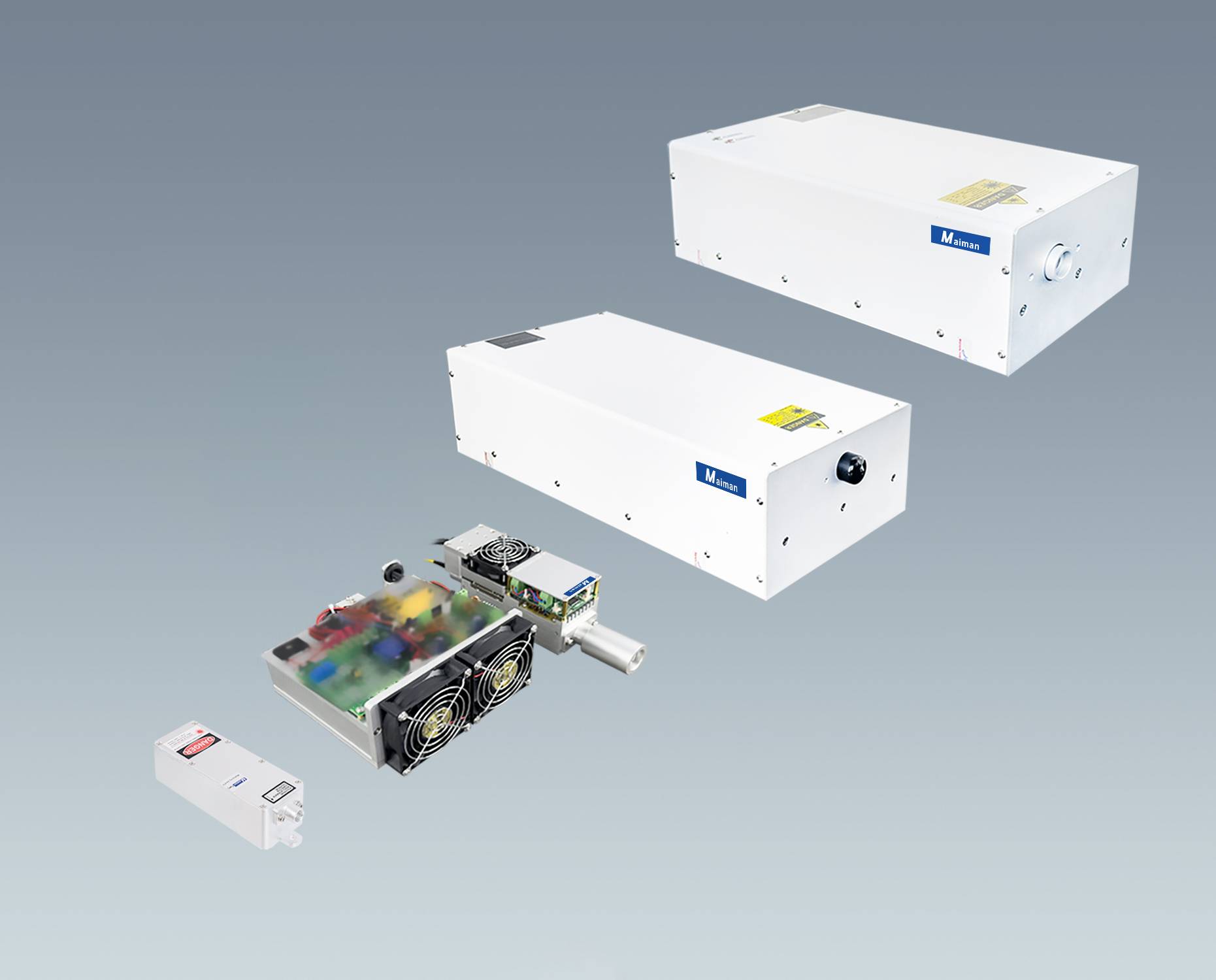

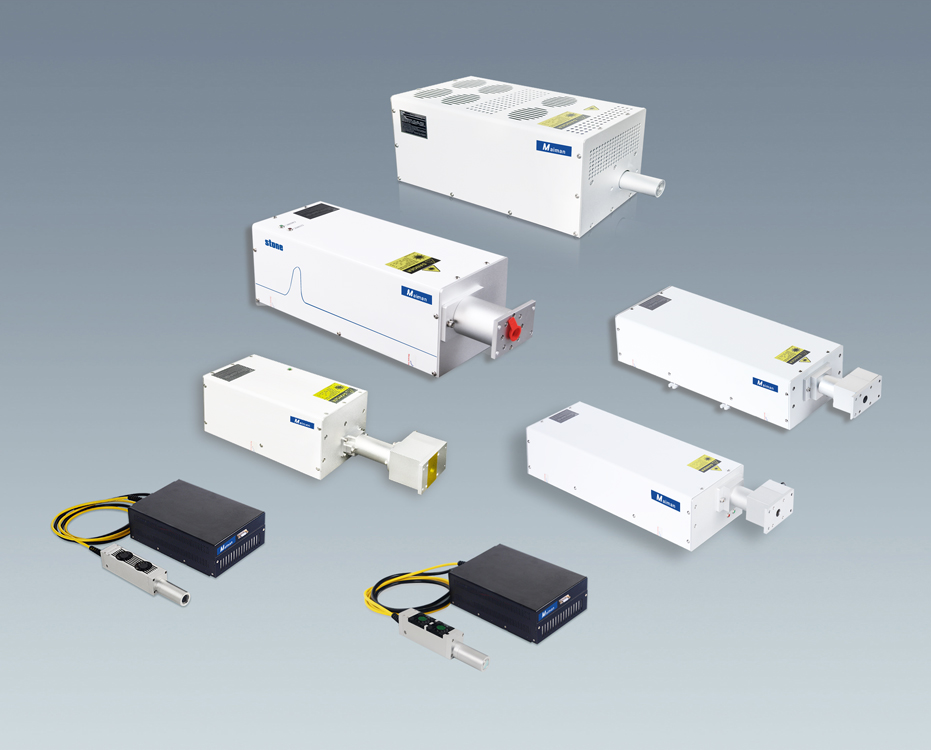

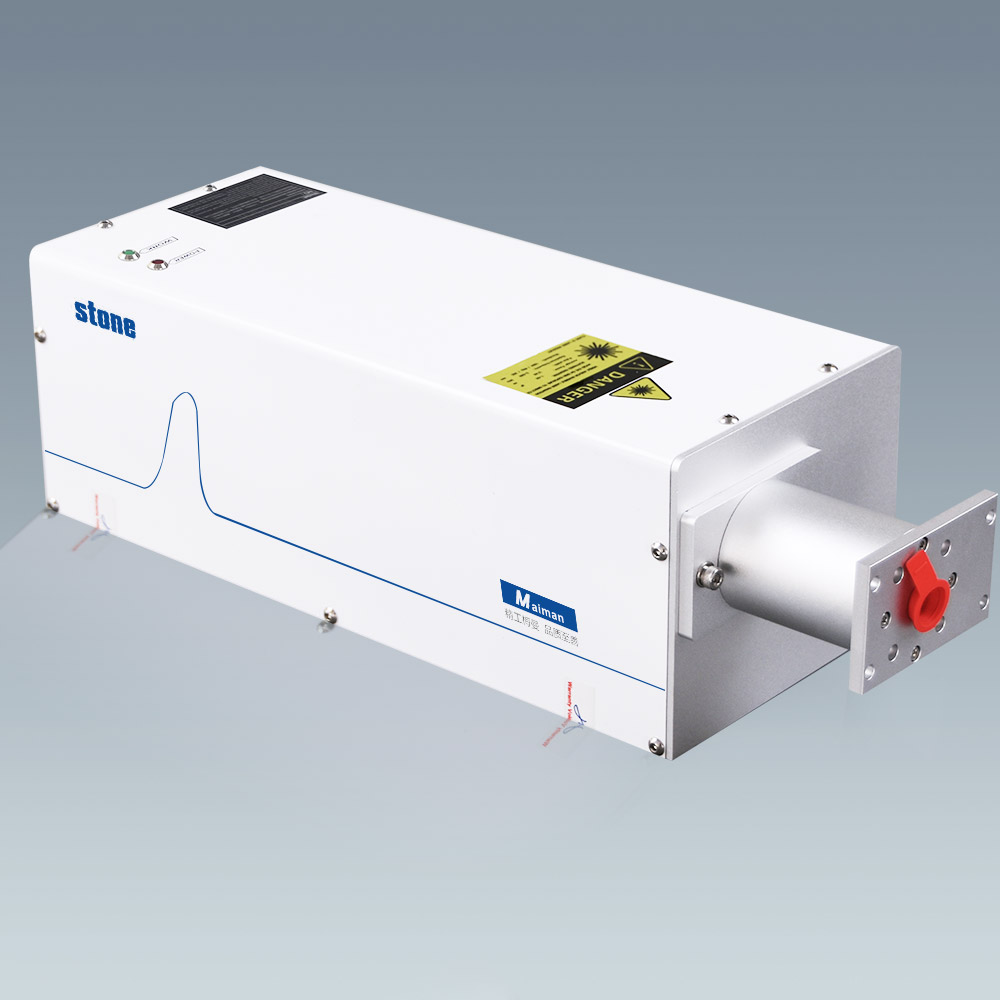

MMEPU-355-3/5/8/10/12/15

All-in-one compact laser source with superior beam quality M²<1.3,it’s capable to process more than 90% of industrial materials with excellent accuracy. Its high stability can meet 7*24 hrs continous working, no worry of power attenuation.

Features:

- The laser power 3-15W;

- Solve power attenuation and meet 7*24 hours of work;

- The service life exceeds 20,000 hours, maintenance-free, no need for regular commissioning;

- All-in-one machine, directly installed with galvanometer, compatible with the rack of fiber laser marking machine;

- 3 layers of protection, protection grade IP65, more suitable for harsh working environment.

Application:

- Material marking – Plastic, glass, metal molds, wood, packaging bags, jade, etc.

- Crystal internal engraving

- 3D printing

- Film cutting