| Model No. | MMEPU-355-10-HE-D30 | |

| Optical Characteristics | ||

| Wavelength (nm) | 355nm | |

| Average Power (W) | >10W@10kHz | |

| Single Pulse Energy (uJ) | ~1000uj@10kHz | |

| Pulse Width (ns) | <30ns@10kHz | |

| Frequency Range | 10-100kHz | |

| Pulse Stability | <3% rms | |

| Long Term Stability | <±3% | |

| Beam Characteristics | ||

| Polarization Ratio | Horizontal;>100:1 | |

| Beam Diameter | ~0.9mm(at exit) | |

| Beam Circularity | >90% | |

| Spatial Mode | TEM00, M² < 1.3 | |

| Operating Specifications | ||

| Warm-up Time | <15 minutes from cold start | |

| Electrical Requirement | DC17.5V,350W | |

| Ambient Temperature | 10-35℃,RH<80% | |

| Storage Conditions | -10-40℃,RH<90% | |

| Physical Characteristics | ||

| Cooling System | Water-Cooled | |

| Water Temperature (laser inlet) | 25℃ | |

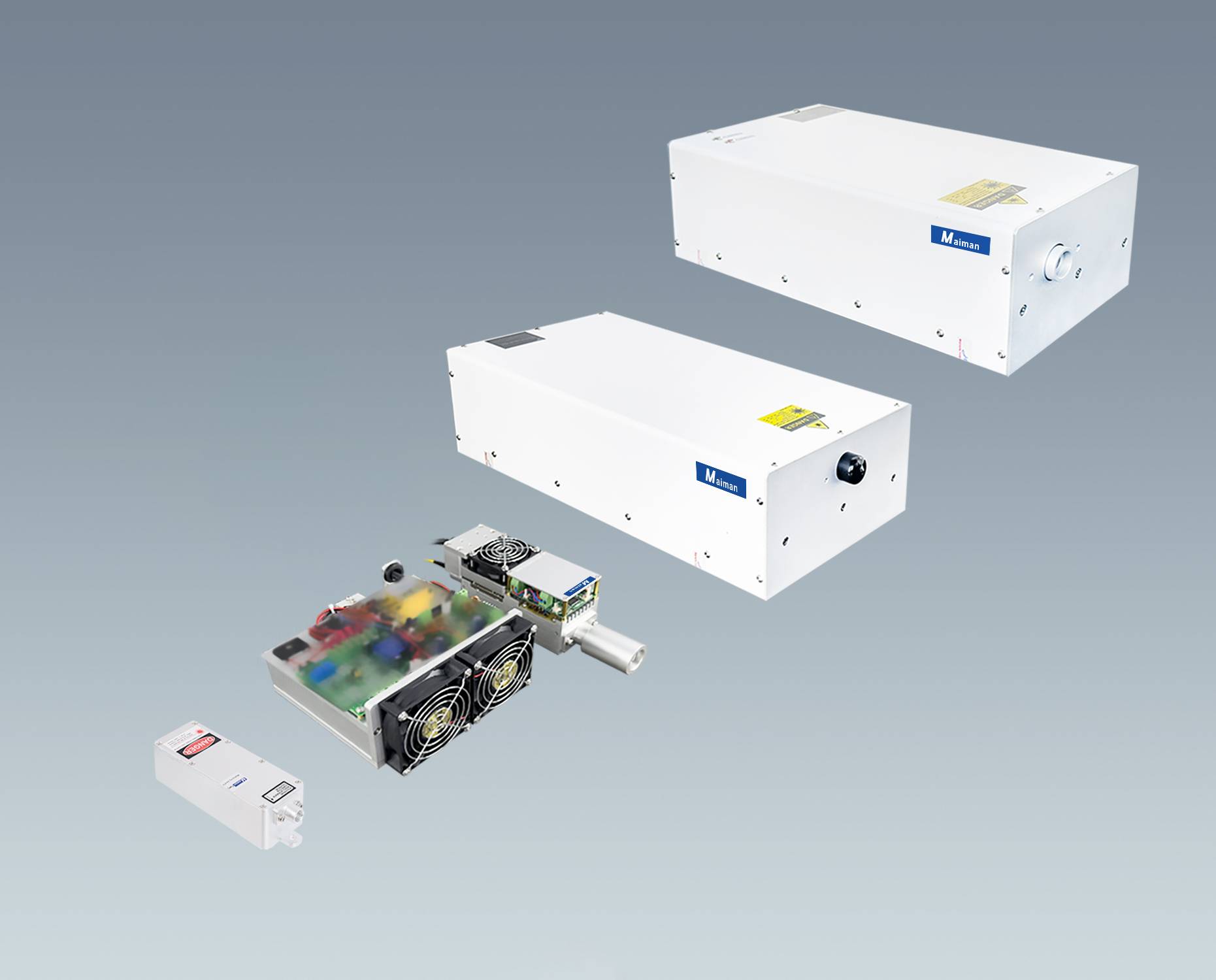

MMEPU-355-10-HE-D30

Low processing heat resulting in less damage to the cut surface so reaches a smoother surface; all-in-one laser design, easy to install and maintain; superior beam quality can achieve deeper and faster processing, more advantageous in cutting SiC, diamond and other super hard materials; self-cleaning system of resonant cavity solves the problem of power attenuation to maintain a long service life.

Features:

- Single pulse energy > 1mj

- Superior beam quality M²<1.3

- Ultra-long service life and power stability

- All-in-one machine mechanism, small size

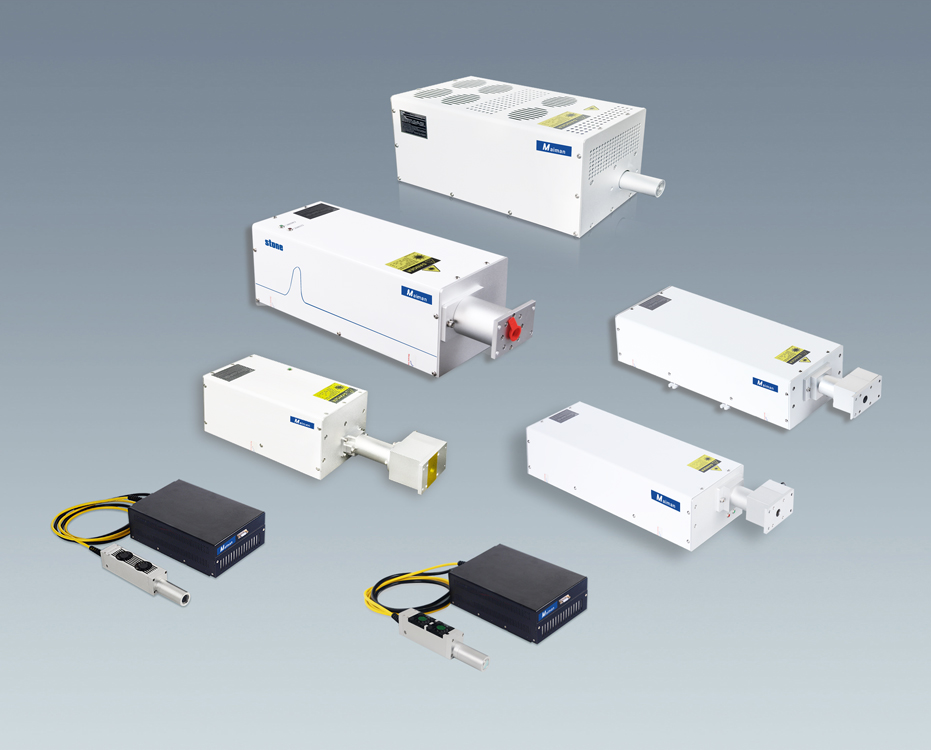

Application

- SiC wafer scribing

- Diamond cutting – Slicing, coring, sawing, faceting, 4 processing

- Cutting of super hard materials – PcBN, PCD, SCD, CVD, SiC, etc.