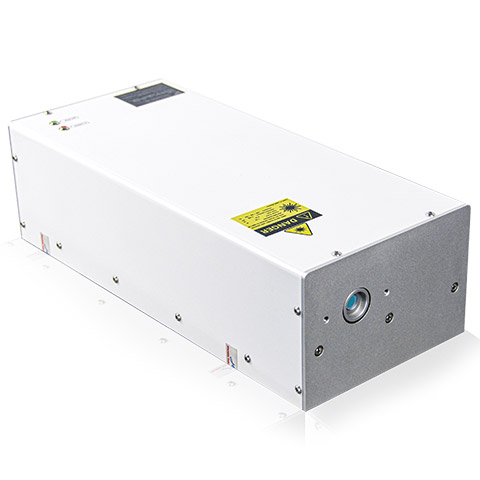

| Model No. | MMEPG-532-16-HE | MMEPG-532-20-HE |

| Optical Characteristics | ||

| Wavelength (nm) | 532nm | |

| Average Power (W) | >16W@10kHz | >20W@10kHz |

| Single Pulse Energy (uJ) | ~1600uJ@10kHz | ~2000uJ@10kHz |

| Pulse Width (ns) | ~20ns@10kHz | |

| Repitition Rate | 7kHz-100kHZ | |

| Pulse Stability | <3% rms | |

| Long Term Stability | <±3% | |

| Beam Characteristics | ||

| Polarization Ratio | Vertical;>100:1 | |

| Beam Diameter | ~1mm(at exit) | |

| Beam Circularity | >90% | |

| Spatial Mode | TEM00, M²< 1.3 | |

| Operating Specifications | ||

| Warm-up Time | <15 minutes from cold start | |

| Electrical Requirement | DC17.5,350W | |

| Ambient Temperature | 10-35℃,RH<80% | |

| Storage Conditions | -10-40℃,RH<90% | |

| Physical Characteristics | ||

| Cooling System | Water-Cooled | |

| Water Temperature (laser inlet) | 25℃ | |

MMEPG-532-HE-D20

Higher peak power of the laser enables greater processing capability and efficiency, particularly in cutting ultra-hard materials, like silicon carbide and diamond.The laser system is highly integrated, incorporating the laser, power supply, Q-switching control, and protection circuits into a compact and easy-to-install unit, facilitating maintenance. The internal resonator cavity is equipped with a self-cleaning system and stable cavity design, addressing power attenuation issues and ensuring an extended lifespan.

Features:

Single pulse energy>1.6mj

Superior beam quality M²<1.3

Ultra-long service life and power stability

All-in-one compact design

Application:

Diamond slicing&coring

Diamond shape cutting(4P processing for 4mm+diamonds)

Carbon fiber cutting

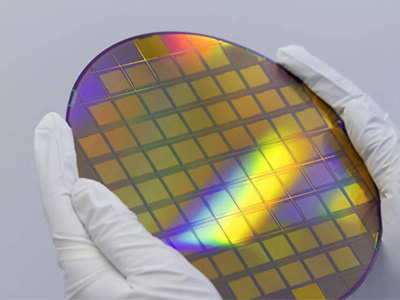

Sic wafer dicing

Super hard material cutting