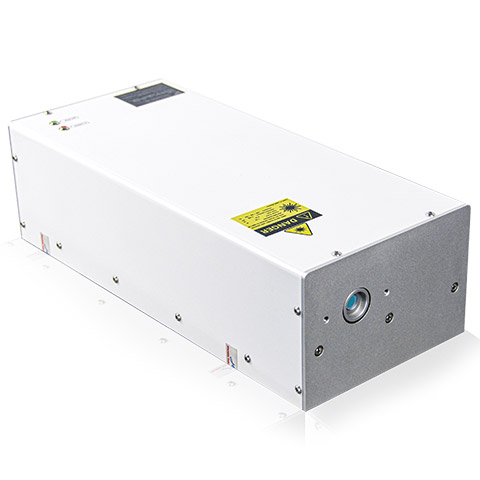

| Model No. | MMEPU-355-10-HE |

| Optical Characteristics | |

| Wavelength (nm) | 355nm |

| Average Power (W) | >10W@10kHz |

| Single Pulse Energy (uJ) | ~1000uJ@10kHz |

| Pulse Width (ns) | <20ns@10kHz |

| Repitition Rate | 7kHz-20kHZ |

| Pulse Stability | <3% rms |

| Long Term Stability | <±3% |

| Beam Characteristics | |

| Polarization Ratio | Horizontal;>100:1 |

| Beam Diameter | ~1mm(at exit) |

| Beam Circularity | >90% |

| Spatial Mode | TEM00 , M²< 1.3 |

| Operating Specifications | |

| Warm-up Time | <15 minutes from cold start |

| Electrical Requirement | DC17.5V,350W |

| Ambient Temperature | 10-35℃,RH<80% |

| Storage Conditions | -10-40℃,RH<90% |

| Physical Characteristics | |

| Cooling System | Water-Cooled |

| Water Temperature (laser inlet) | 25℃ |

MMEPU-355-HE-D20

Cold light laser, cuts off molecular bonds to achieve lower processing heat, the cut surface is smoother with less damage; high power, high energy and narrow pulse width enable the laser to have higher peak power, endowing the laser with greater processing capacity and efficiency, so has more advantages in cutting superhard materials such as SiC and diamond; highly integrated laser with driver, Q driver and protection circuit, all-in-one machine structure is convenient for installation and maintenance; the resonant cavity self-cleaning system and stable cavity design solve the problem of power attenuation to achieve a ultra-long service life.

Features:

- Single pulse energy > 1mj

- Superior beam quality

- Ultra-long service life and power stability

- All-in-one machine mechanism, small size

Application

- Carbon fiber cutting

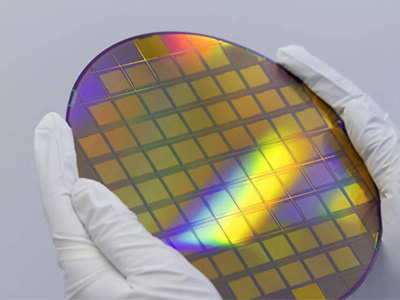

- SiC wafer dicing

- Diamond cutting – slicing and coring

- Super hard material cutting – PcBN, PCD, SCD and CVD diamond, SiC, etc.