Solutions for marking, punching and cutting in the PCB industry

PCB applications are becoming more and more popular and the demand for PCB marking is increasing. Which lasers are more suitable for industrial applications? Is there a low-cost integration route?

- PCBMarking

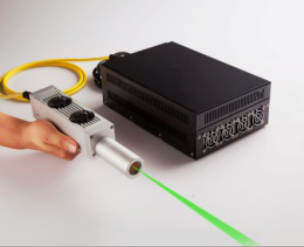

For PCB marking, ultraviolet laser is a very good light source. In addition, the fiber-type green laser produced by Maiman is also a good choice. It is not only low in cost, but also has a good marking effect.

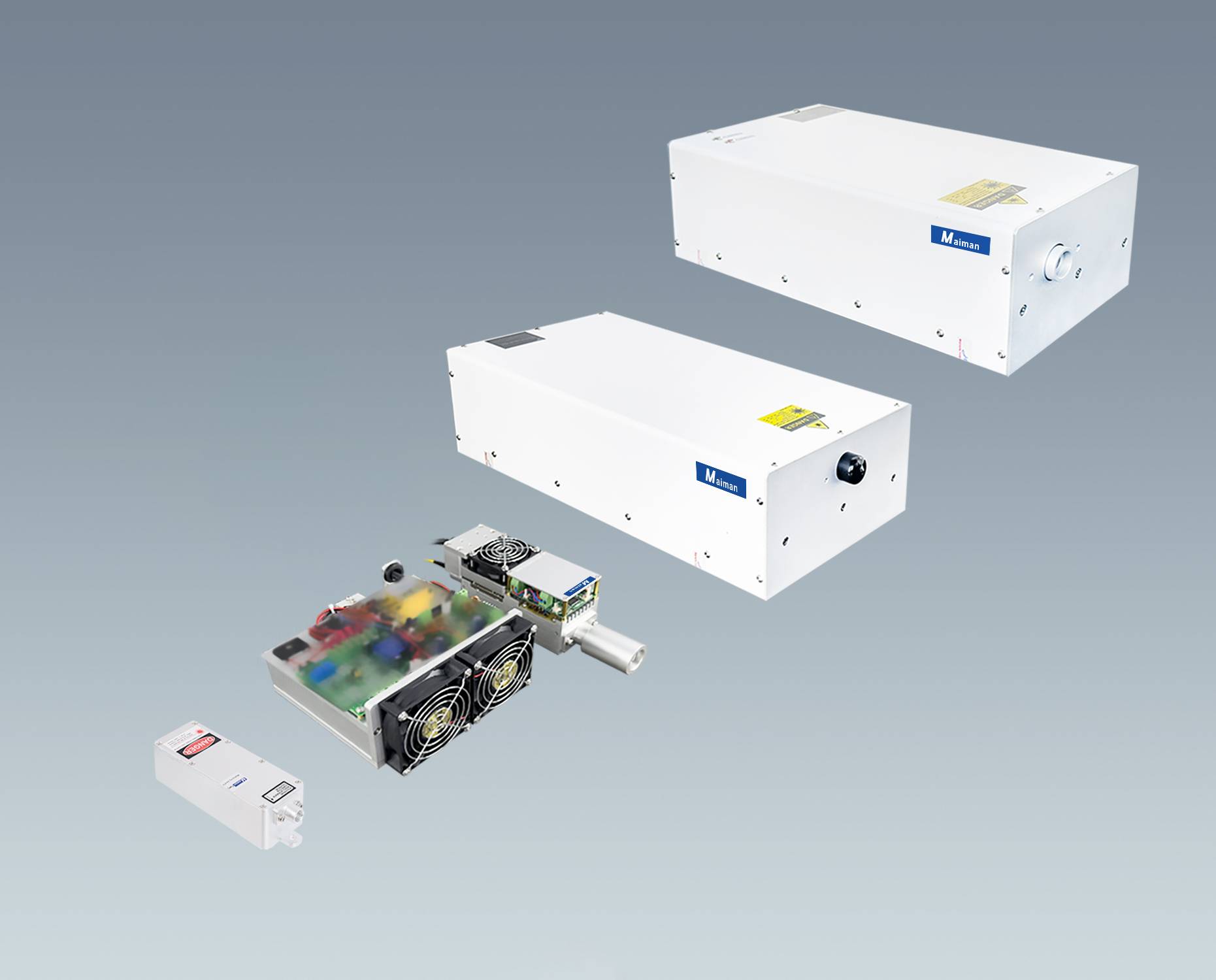

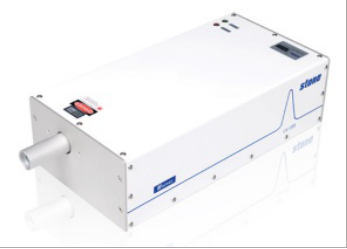

Fiber Type Green Laser

Product Features:

- Insulation film marking

- Low failure, long life

- Ease of integration

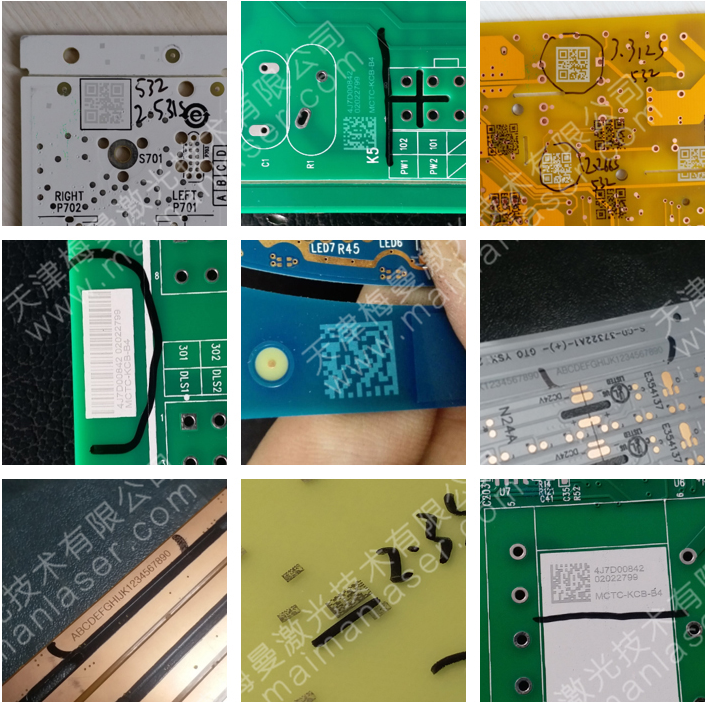

PCB Marking Cases

- PCB Cutting and Drilling

Such applications generally use high-power ultraviolet lasers or green lasers and green lasers are more likely to cause carbonization. For high cutting requirements, it is recommended to use a high-power ultraviolet laser.

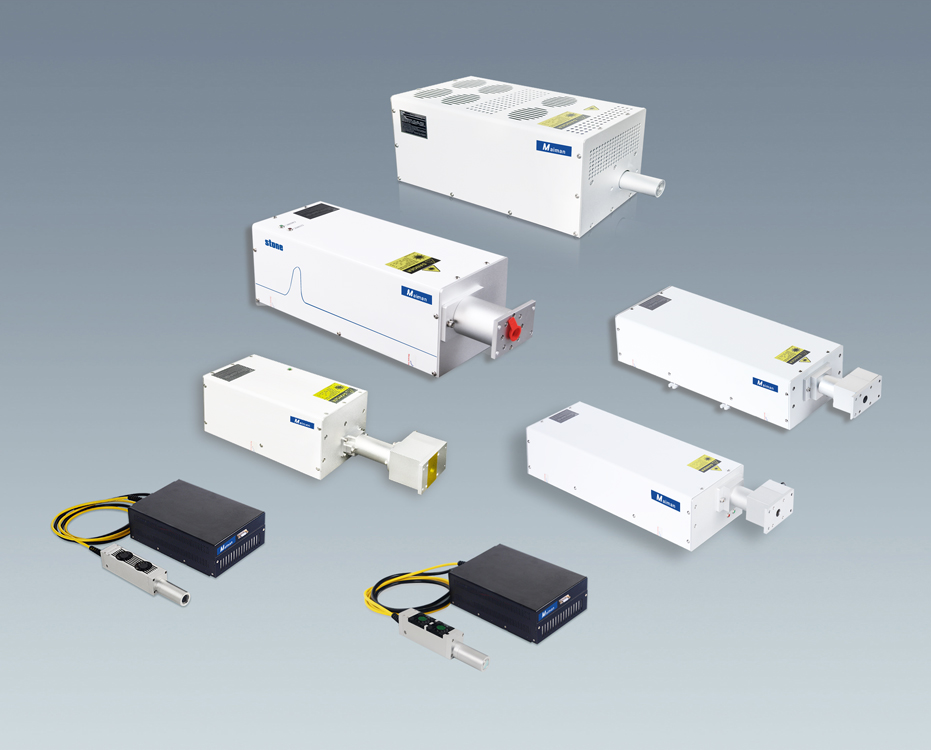

12W-20WHigh Power UV Laser

Features:

- Long life, maintenance-free, no need for regular calibration of the light path

- Easy to install, all-in-one machine no additional power supply, and the galvanometer can be directly installed

- Reduces cost, no optical path, compatible with optical fiber racks

PCB Cutting and Drilling Cases

Ultraviolet lasers have stable performance, low power consumption, small thermal impact, wide application range, fast marking speed, high efficiency, small spot, high beam quality and can be matched with production lines.

Cold Light Laser Processing Solution

Transparent Button Paint Stripping Solution

Electronic Device Marking Solutions

Food Packaging Solutions

FPC cutting Solution

Glass Engraving Solution

Gem Drilling Solutions