Packaging

- Home

- /

- Applications

- /

- Packaging

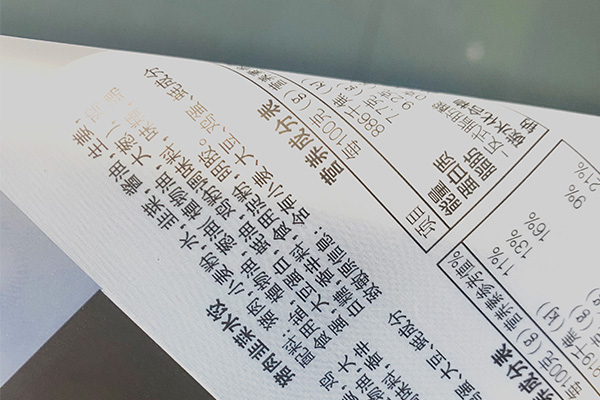

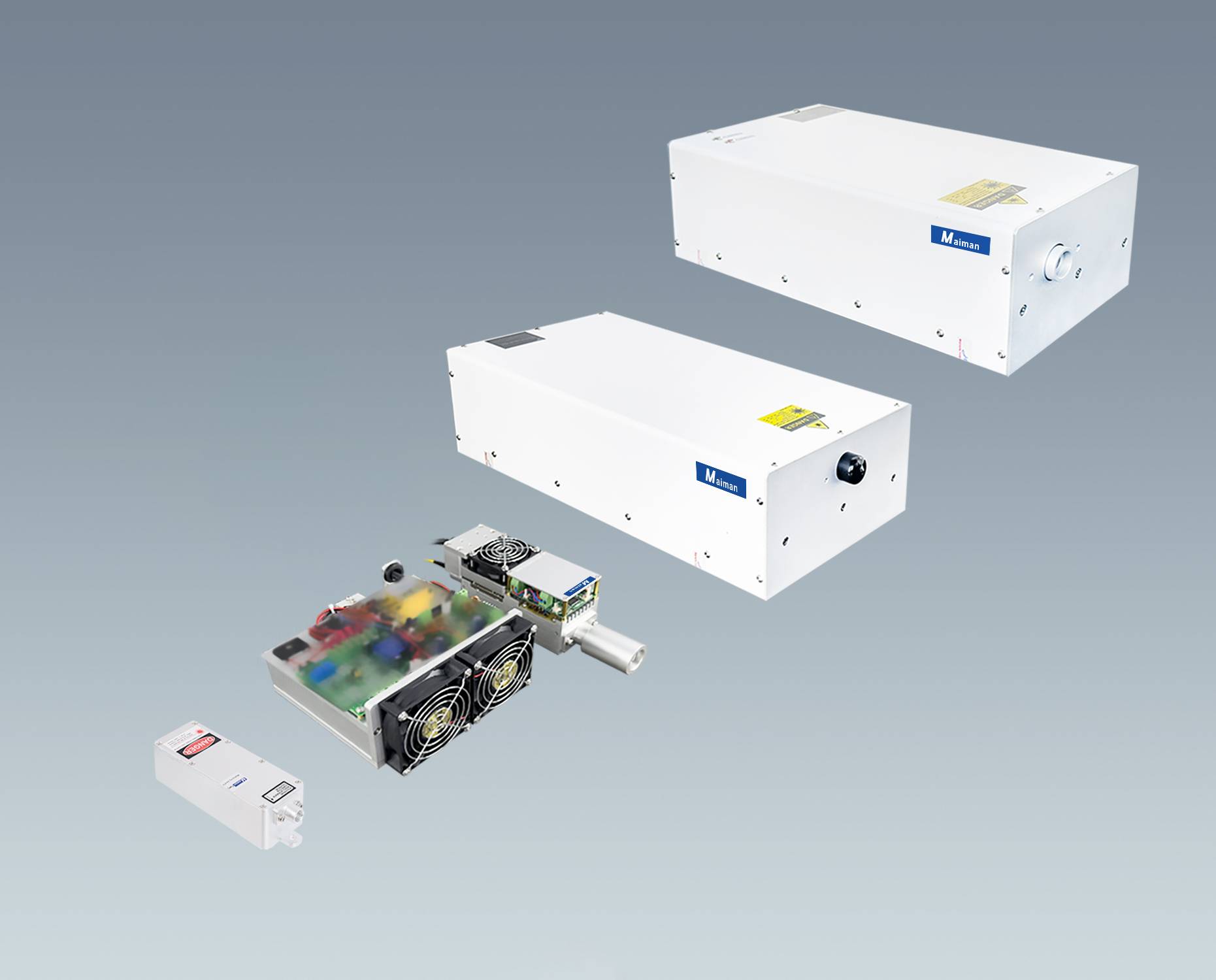

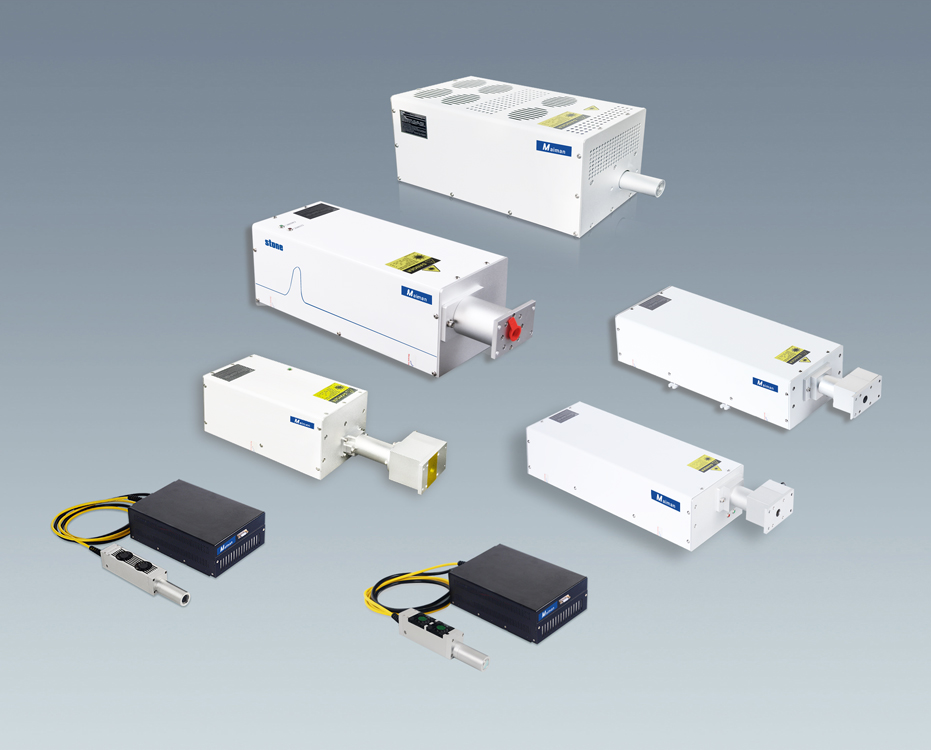

Because of its safety, environmental protection, pollution-free, and non-modifiable features, laser marking is gradually replacing traditional inkjet marking, and has quickly won the favor of customers in terms of food traceability and anti-counterfeiting. As the designated laser source supplier of Sanquan Foods (one of the largest food groups in China https://www.sanquan.com/), Maiman Laser has served the food processing industry for many years and has accumulated rich experience. For example, Maiman lasers have excellent performance in marking various packaging materials, punching and marking perforated packaging, marking fruits and eggs , etc.

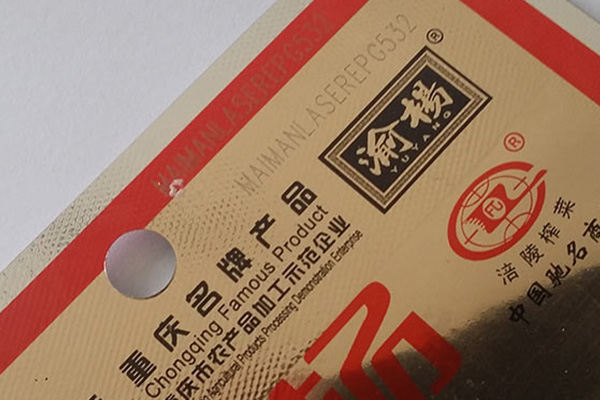

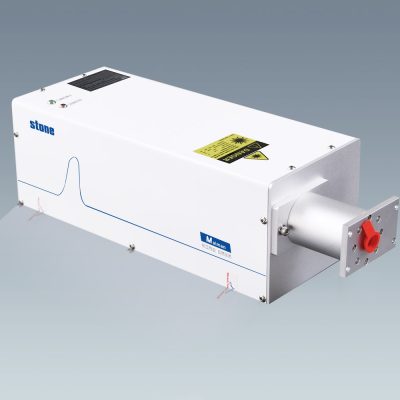

At present, the packaging materials on the market are mainly composite multi-layer materials, and each layer of materials has different characteristics during processing, so the requirements for lasers are relatively high. Advantages of Maiman UV laser for marking packaging materials:

1) Clear marking effect, while the surface of the marking is smooth and almost untouched.

2) No blistering effect, because UV processing is cold processing, the thermal effect is extremely low, and will not cause different deformations in each layer of the multi-layer composite material, which is different from the fiber laser.

3) Minimal damage to the packaging material guarantees the strength, and prevents punctures that may cause air leakage and also prevents damage during the extrusion process.

4) For the material with aluminum film, the aluminum film will not be damaged while still achieving clear marking, so the food will not deteriorate rapidly due to light transmission.

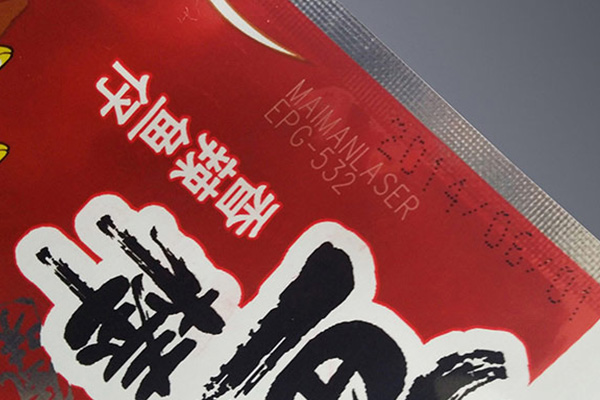

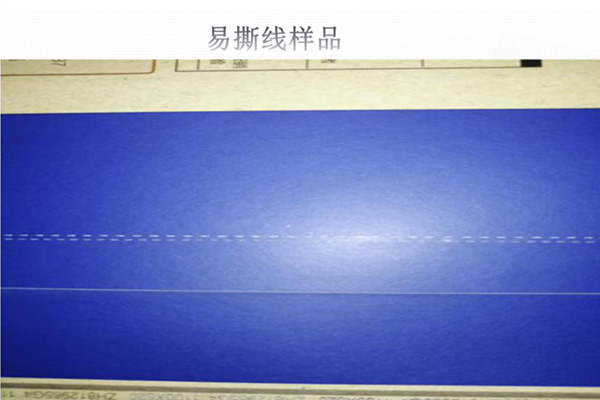

Perforated Packaging

Laser scribing is used for easy-to-open packaging, such as thin film air holes, easy-to-tear openings, laser marking of heat-sealed labels, and perforation of breathable packaging, etc., in PVC, PE, PET, AOPP, MOPP, multi-layer composite film and other packaging materials can be easily realized.

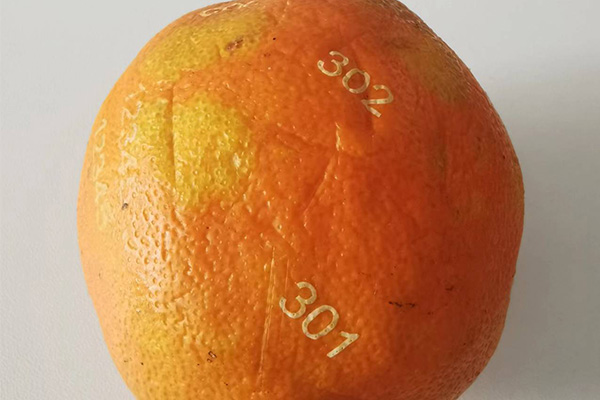

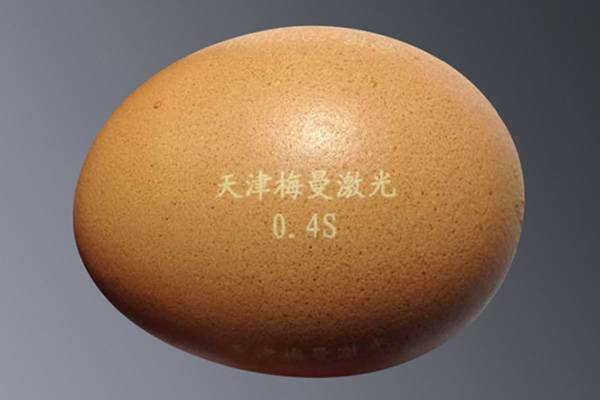

Fruit and egg marking

Using laser marking technology to mark oranges, apples, eggs, etc. has the advantage that it only needs to remove a small amount of pigment from the outer layer of fruits and eggs, which is very environmentally friendly and will not affect the freshness of food. As no additives or stickers/packaging of any kind are used, not only are plastics and papers saved, but there is also a significant reduction in energy consumption and emissions: laser marking requires only a fraction of the energy required for stickers.