Diamond & Jewelry

- Home

- /

- Applications

- /

- Diamond & Jewelry

Diamonds and Jewelry

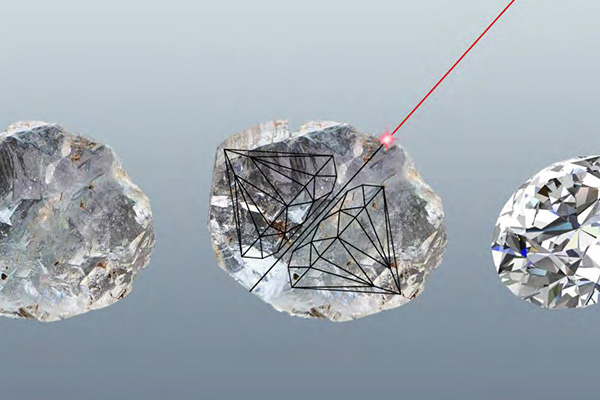

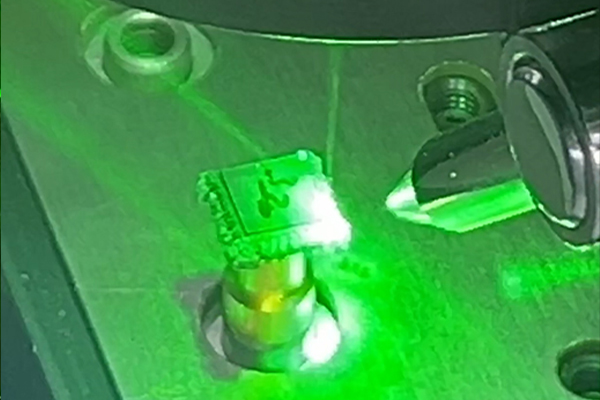

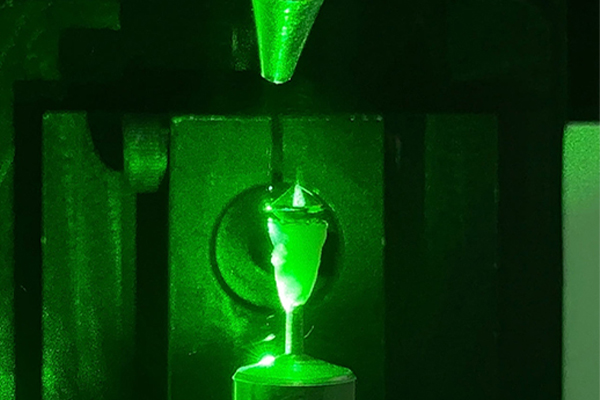

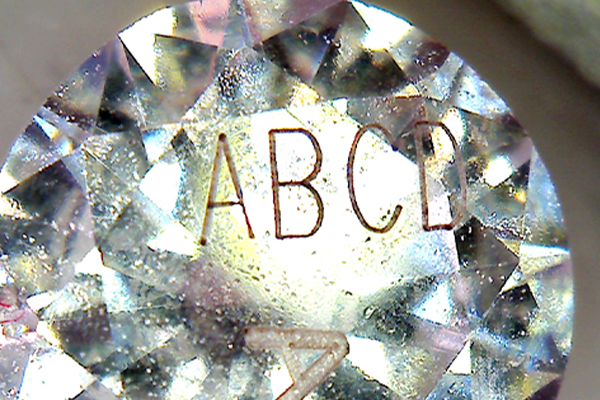

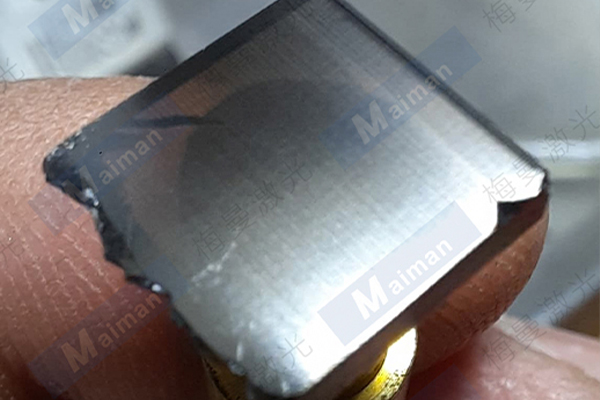

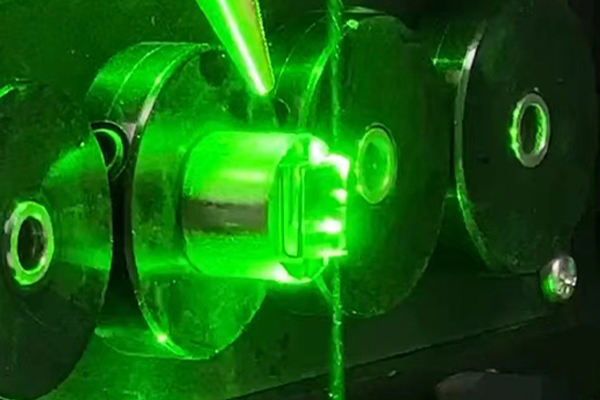

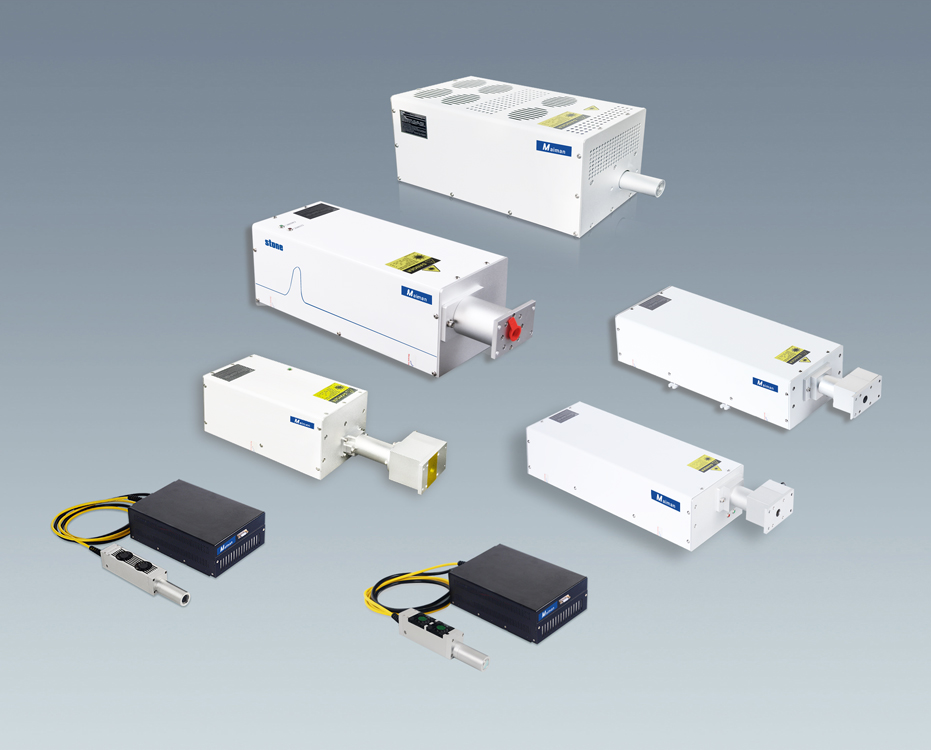

Maiman Laser has designed and developed a variety of solid-state lasers specially for the diamond processing industry, covering multiple wavelengths such as green (532nm), ultraviolet (355nm) and infrared (1064nm) with laser power range between 10-30W. Taking into account the application requirements of slicing and coring, sawing, fancy cutting, planning and marking of natural diamonds and laboratory-grown diamonds (CVD, HPHT), it is the ideal laser source for manufacturers of diamond processing equipment such as laser diamond cutting machines, 4p diamond laser machines and diamond planning machines.

In the process of diamond processing, smaller weight loss, smaller breakage rate, smoother cut surface effect and higher production efficiency are pursued. Maiman’s diamond processing laser is designed for modern mass production environment and on the basis of the diode solid-state pump laser technology, the beam quality, peak power and pulse energy are improved, thereby reducing material loss in diamond processing and improving processing accuracy, so it is very suitable for large-size, high-precision diamond processing.

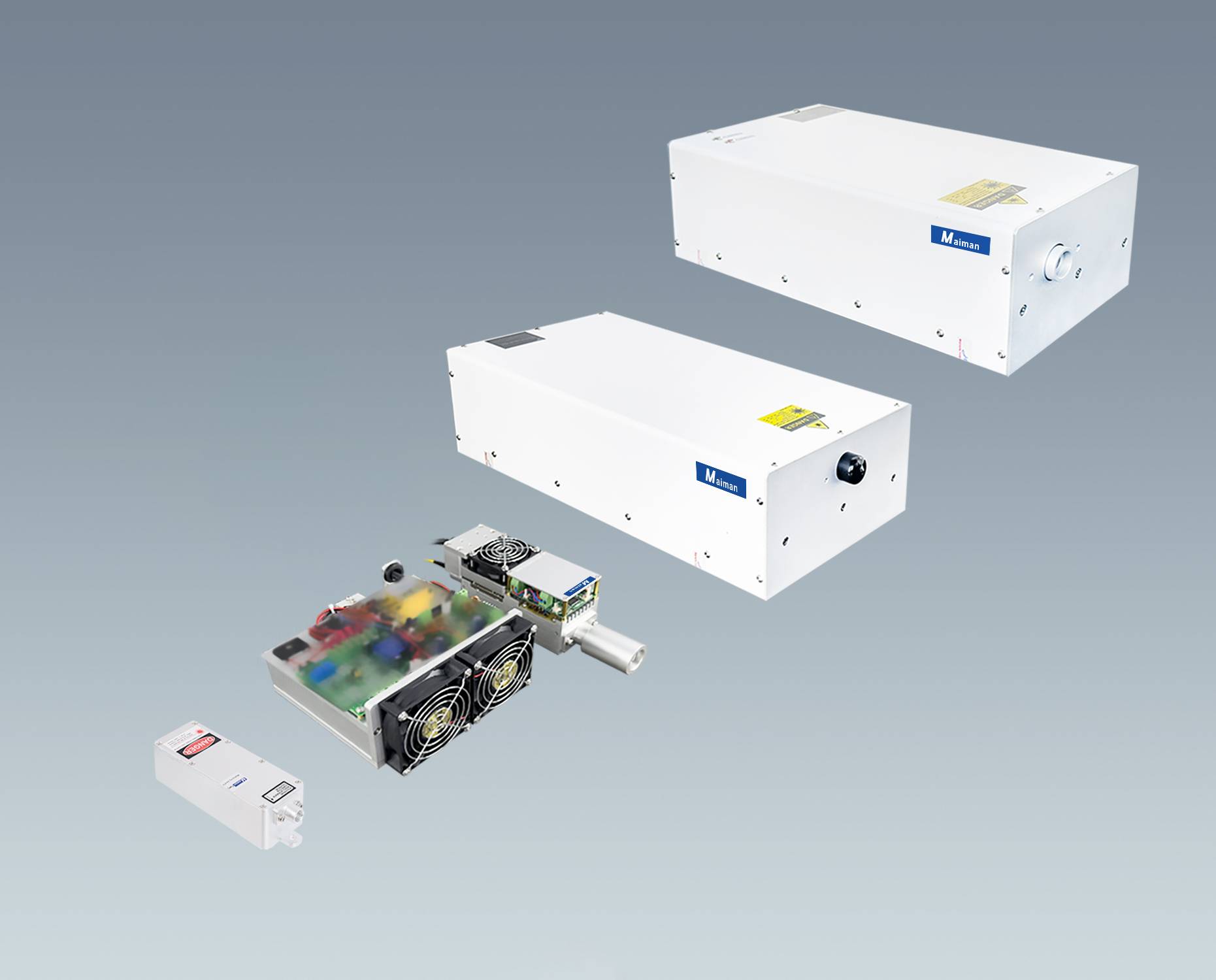

Compact all-in-one design and flexible control mode, easily compatible with hardware and software systems of diamond processing equipment. Since the laser source, Q driver, and laser power supply are highly integrated into one box, there is no need to purchase additional optical components and parts which greatly saves costs. The solid-state laser technology route perfectly solves the problem of laser power attenuation and does not require regular manual intervention, debugging and calibration. Compared with traditional side-pump lasers, it has a longer life and has obvious advantages. Maiman Laser is currently becoming the choice of more diamond equipment manufacturers from India, Israel and other countries.